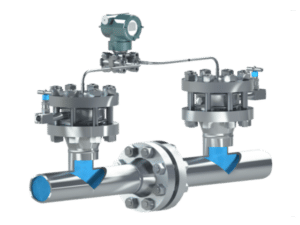

INTRODUCING BOTH DESIGNS

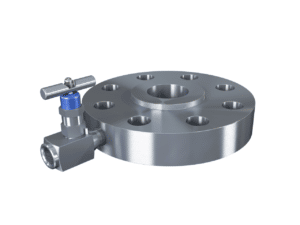

A flush ring construction, as the name suggests, is based on a circular ring that is positioned (sandwiched) between the diaphragm seal and the process nozzle. This ring is usually made of the same material as the wetted parts of the instrument and allows for flushing and calibrating the instrument. It has a gasket area matching the diaphragm seal flange and conforms to the flange design standard. The gasket facing is unique to to the process requirements and is designed to provide a tight seal between the two components. The gasket area of the flush ring is equivalent to the gasket area of the blind flange of the process connection and diaphragm seal. The flush ring is typically clamped into place and does not have any bolt holes.

flush flange and reducer flush flange

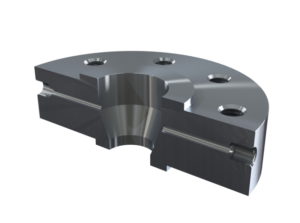

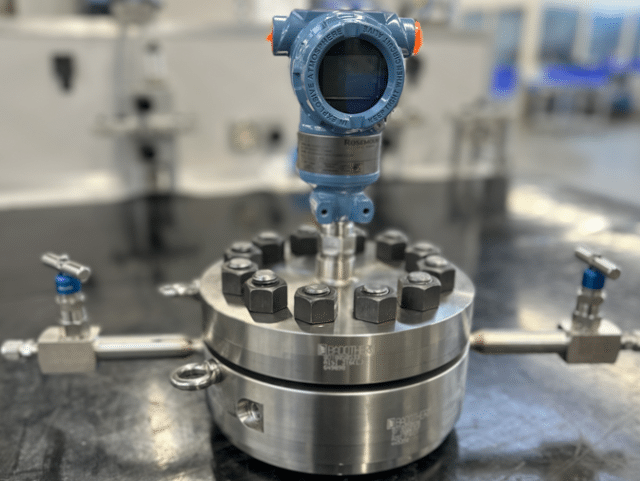

A flush flange has the same dimension and bolt holes as a blind flange of the same size. It is machined from a solid bar material, such as forged stainless steel or any other exotic material, and has the required gasket facing on both sides to provide a tight seal to both the process nozzle as well as the diaphragm seal. A special type of flush flange also allow as an enlarger or reducer flange, to enable larger ” blind flange diaphragm seal to a smaller process connection. These reducer flanges can come in many designs and often include a significant weight. They can have an centric design or an eccentric design, to avoid residue to built up in the dead corners.

Both flush ring and flush flange constructions have their own unique advantages and disadvantages, which we will explore in depth in the following sections of this blog post.

A CLOSER LOOK AT THE PROS AND CONS

When considering the requirements of pressure measurement applications, there are several key factors to consider, including ease of installation, safety, interchangeability, standardization, and cost price.

From an installation and safety perspective, flush flange constructions offer several advantages. The bolt holes on the diaphragm seal allow for the flush flange to be positioned gradually and efficiently, reducing the risk of damage to the diaphragm or gasket. Additionally, the bolts provide a better positioning of the gasket between the diaphragm seal and the flushing construction, reducing the risk of leakage and ensuring the safety of the instrument. So with flush flanges the gasket is always centered correctly and there are no gasket dimensional challenges. Also, the flush flange has the same gasket connection as the blind flange, so less chance for damage on the diaphragm. For this reason, the actual end user of the instrument, often prefer the flush flange construction. The ease of installation and the reduced risk of damage and the higher safety this design offers, makes it the preferred design.

However, when it comes to standardization, and cost price, flush ring constructions are often a preferred choice. For this reason EPC often standardize on this design. The flush ring has a “one size fits all” approach for standard RF facings per size (cl. 150 to 2500), allowing for easy component interchangeability and standard stockkeeping. Additionally, since the material required for a flush ring is much less, the cost price is also reduced and less machining is required. Less material also means reduced weight, which in some constructions also can be a point of consideration.

It’s important to note that while flush rings are cost-effective and offer advantages in terms of interchangeability and standardization, they can be more difficult to install and require an extra pair of hands to keep the ring in place during the installation process.

In conclusion, each design has its own unique strengths and weaknesses, and the best choice will depend on the specific requirements and needs of your pressure measurement application.

More information:

Datasheet: Flush rings

Datasheet: Flush flanges

Datasheet: Reducer flanges

Datasheet: Instrument needle valves

Blog: Special flush constructions

Blog: Understanding the various names and functions of flush rings