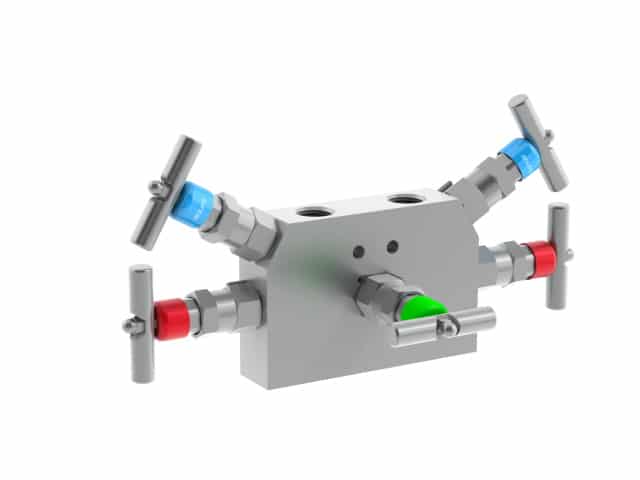

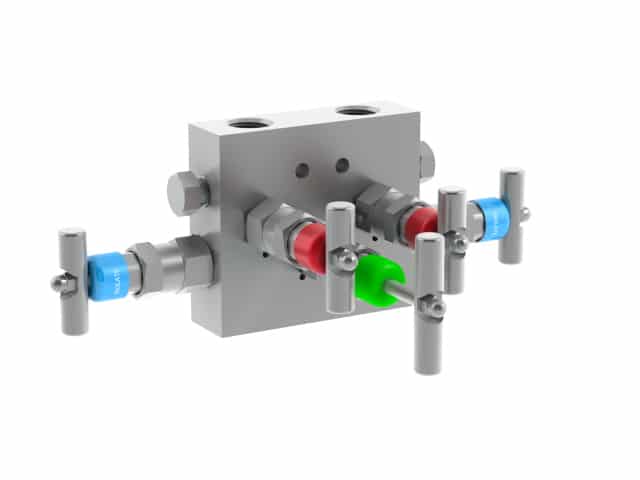

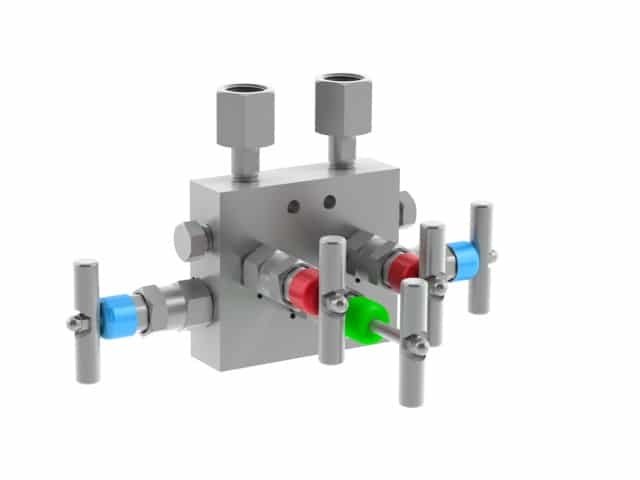

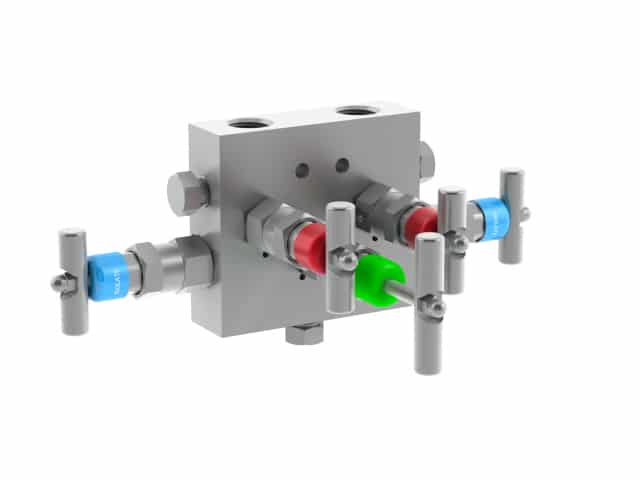

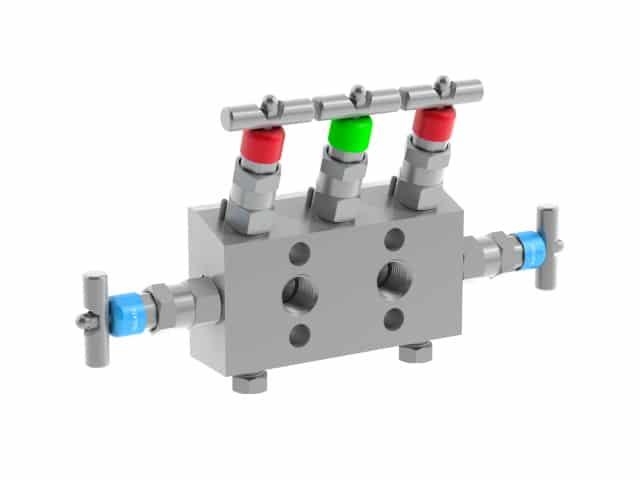

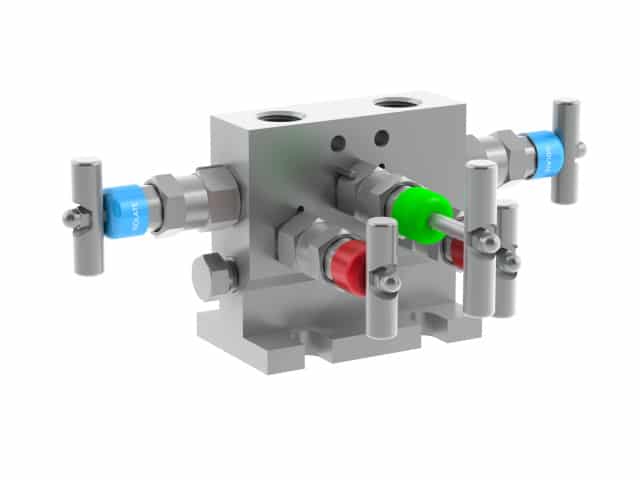

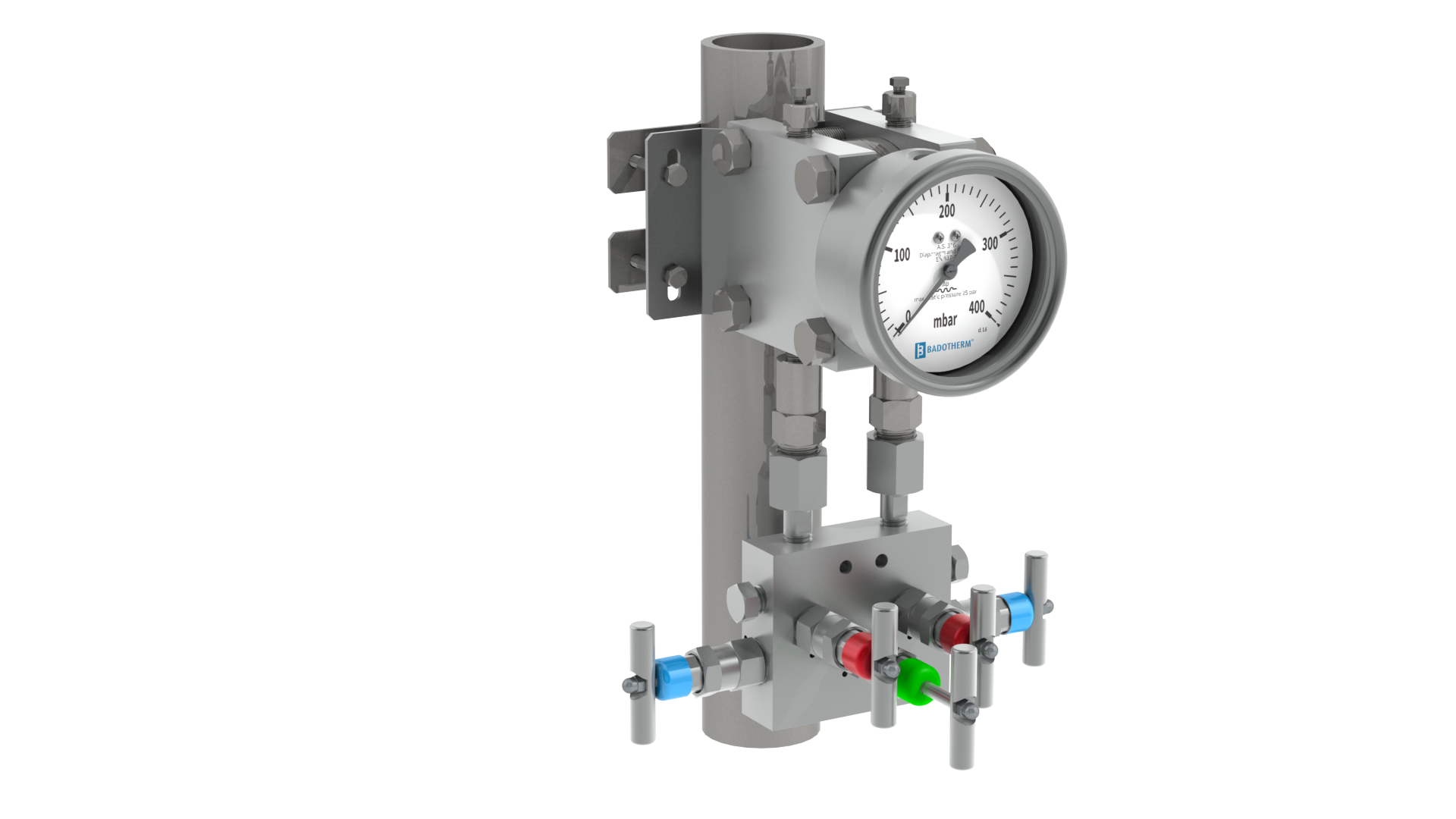

Five valve manifolds

The Badotherm five valve manifolds are mainly used on differential pressure instruments. With the function of the five valve manifolds you can isolate the high and low instrument individually, equalize both sides or vent the individual sides. This all make it suitable for use on differential pressure transmitters as well as on the BDT13 differential pressure gauge and the PTH diaphragm seal solution.